09 August 2016

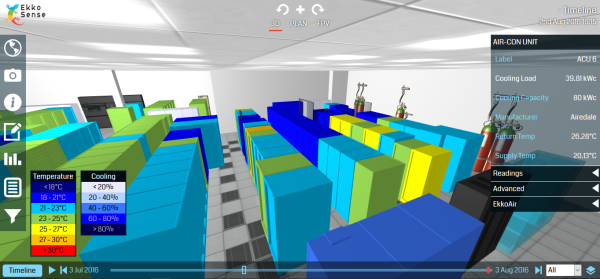

EkkoAir uses “powerful” 3D gaming technology to offer a true an all round view of a data centre’s physical and thermal dynamics.

EkkoSense has launched what’s claimed to be the world’s first IoT monitoring solution to track data centre cooling loads in real-time.

The Nottingham-based data centre thermal risk specialist says EkkoAir can be simply fitted to any cooling unit in moments, and allows operators to wirelessly monitor thermal instabilities right across the data centre.

It says that, for the first time, users will be able to balance thermal profiles so that only those cooling units that need to be working are actually active. By concentrating on actual cooling duty information, EkkoSense estimates that data centres can improve their overall energy performance by up to 30 per cent.

According to the company’s CTO, Dr. Stu Redshaw, traditional data centre cooling approaches are still built around the nominal main plate ratings declared by cooling equipment manufacturers.

“Building a cooling strategy based on plate ratings might have once seemed smart, but it’s an outmoded approach that has systematically led to both under-cooling or over-cooling, resulting in either unacceptable thermal risks or unnecessary energy consumption right across our industry.”

EkkoSense CTO Dr. Stu Redshaw estimates that overall energy performance can be improved by up to 30 per cent.

Redshaw says innovations in low-cost sensor technology, IoT, gaming technology and cloud have enabled EkkoSense to bring a completely new level of thermal monitoring performance.

EkkoAir is said to uniquely offer “true” real time cooling duty information. The company says this helps data centre operators reduce risk by identifying those faulty or non-performing cooling units that don’t get picked up under routine maintenance.

It adds that it can also help them optimise capacity by accurately identifying spare capacity based on actual cooling duty loads, and improve overall data centre energy performance by up to 30 per cent by focusing in on inefficient or redundant cooling units

By capturing information that was previously unavailable, and by being able to track temperature differentials either at an individual unit or data centre level, EkkoSense says operators can now track motions of heat across the floor and reveal new insights into the underlying physics of cooling data centres.

“By taking the guesswork out of data centre cooling, EkkoAir provides operators with the real time information they need to really start addressing the inefficiencies that currently make cooling their largest operational overhead,” says Redshaw.